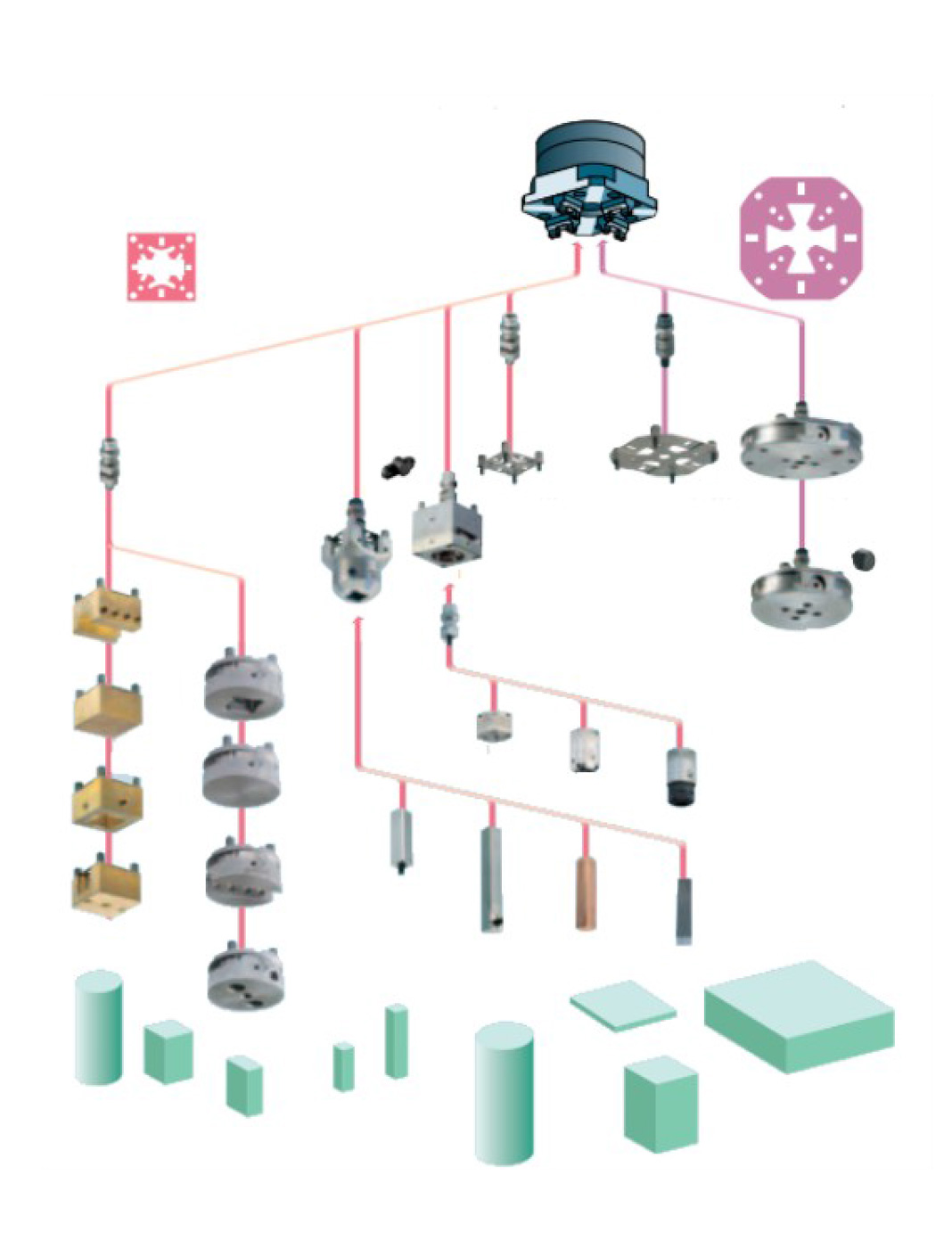

The company is a professional enterprise engaged in the promotion and application of automatic rapid positioning fixture system for mold processing. It is committed to bringing the manufacturing management level of national mold industry into line with the international standard, improving the manufacturing precision, high efficiency and low cost core competitiveness of local mold enterprises, and creating value for customers with the concept of cooperation and co-existence. The rapid positioning fixture system is applied to CNC milling machine, EDM, WEDM, wire cutting, CNC turning, CNC grinding machine, CMM, three coordinate and other mold processing The discharge and detection machine tool can greatly reduce the alignment and calibration time of workpieces in each process and the number of touch points, improve the machining accuracy, and reduce the human error and accumulated error caused by repeated positioning of each process of the machine tool.

(1) Advantages of good precision mold processing automation and rapid positioning fixture system:

1.1 standardized interface - various fixtures cooperate with various machine tools through the mutual combination of positioning pull rods and positioning spring pieces;

1.2. The unique zero datum - the machining process of each machine tool in the mold processing process does not need to align the calibration table and touch number score;

1.3. Reduce the processing preparation time of the machine tool - the effective working time of the workpiece processed by the machine tool in each process is increased by 30% - 60%;

1.4. Reduce the machine tool equipment and labor costs - the capacity of EDM spark discharge motor is 3 sets, which exceeds the traditional method of 4 sets, saving hundreds of thousands of yuan in equipment investment;

1.5 reduce the consumption of electrode copper and graphite -- reduce the consumption of electrode by 30% - 50% through the use of electrode clamp base and electrode embossing extension rod;

1.6. Die repair emergency workpiece insertion processing - fixed reference point and repeated accuracy of the system can interrupt the workpiece being processed, and continue to process the unfinished workpiece after completing the emergency workpiece processing, without correction and readjustment.

(2) What can you get by using the accurate and fast positioning fixture system?

2.1. The shortest mold delivery time

2.2. Lowest mold production cost

2.3. The most easily controlled mold processing accuracy

2.4. The most flexible production plan adjustment

2.5. Simple and rapid technology development of new employees we provide not only jigs, but also complete implementation scheme of automatic repeated positioning jig system for mold processing! Perfect and thoughtful installation and training services! Contact us now!

7

Industry construction experience500

Common choice of customers20

Professional technicianAddress: 1st floor, No. 22-9, Yumin Road, Shatou Industrial Zone, Shatou community, Shajing street, Bao'an District, Shenzhen

Tel: 0755-85278645

Fax: 0755-85256521

Q Q: 2224815514

E-mail:sales@hjz-jiaju.com

website:www.hjz-jiaju.com